Plug and feather, also known as plugs and wedges, feather and wedges, wedges and shims, pins and feathers and feather and tare, refers to a technique and a three-piece tool set used to split stone.

Wedge and shims are a kind of manual tools that uses manpower to impact the metal wedge into holes on stone, thereby split stone. It is mainly used in splitting cracked stone and arch stone which by utilizing a wedge set can be separated into smaller or standard stone blocks. Wedge can also trim relative large and irregular stone blocks.

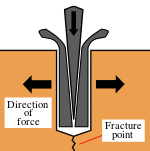

Each set wedge and shims consist of a metal wedge, and two shims. The shims are wide at the bottom, and tapered and curved at the top. When the two shims are placed on either side of the wedge, the combined width of the set is the same at both ends. The depth of drilled hole depends on the length of wedge.

Specifications:

| Hole Size (mm) | 14 | 16 | 20 | 24 | 32 | 34 | 38 | 38 |

| Length (mm) | 125 | 125 | 190 | 200 | 270 | 280 | 325 | 600 |

Technique:

Multiple sets of plug and feathers are typically used to split a single, large piece of stone. The stone is first examined to determine the direction of the grain. After the location of the intended split is chosen, a line is scored on the surface of the stone. A number of holes are then cut or drilled into the stone face along the scored line approximately 10 – 20 cm apart. Plug and feather sets are then inserted in the holes with the “ears” of the feathers facing the direction of the desired split. The plugs are then struck with a small stone maul in sequence. An audible tone from the wedges changes to a ‘ringing sound’ when the wedges are tight. Between each series of strikes, a pause of several minutes allows the stone to react to the pressure. Eventually a crack appears along the line that was scored on the surface and the stone splits apart.

Feathers:

1.Mainly rely on manpower, therefore labor intensive, and have difficult working conditions.

2. Suitable for mining where lack of power, water supply.

3. Suitable for quarrying layered ores which are either horizontal or gently inclined, have layer depth around 1.5m.

4. Can apply desegregation and separation of large stone blocks quarried through other methods.

5. It is easy to handle with and maintains its value in mines of which have better rock fracturing performance and low mechanical level.

We are a supplier of plus and feathers. Here are the specifications below.